“To find out what happens to a system when you interfere with it, you have to interfere with it (not just passively observe it).” – George Box

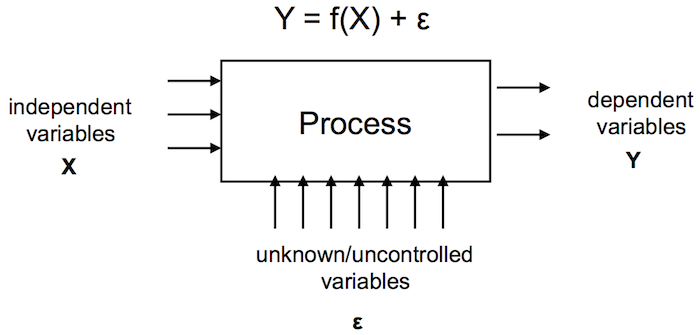

This practical workshop is designed to equip any candidate considering making adjustment to see what happens to its present work process. For career consideration, the Design of Experiment (DOE) will arm you with one of the foremost tool for designing and improving any business process. This statistical tool is popularly employed in the DMAIC improvement phase of Six Sigma but can be applied to any quality or continuous improvement initiative.

As far back as 1996, Rita Koselka listed the following benefits to DOE in a Forbes magazine article titled “The New Mantra: Multivariable Testing (MVT)”;

- Reducing the rejection rate of a touch-sensitive computer screen from 25% to less than 1% within months.

- Maintaining paper quality at a mill while switching to a cheaper grade of wood.

- Reducing the risk of misusing a drug in a hospital by incorporating a standardized instruction sheet with patent-pharmacist instruction.

- Reduce the defect rate of the carbon-impregnated urethane foam used in bomb from 85% to zero.

- Improving the sales of shoes by using an inexpensive arrangement of shoes by color in a showcase, rather than an expensive, flashy alternative.

- Reducing errors on service orders while at the same time improving response time on service calls.

- Improving bearing durability by a factor of five.

WORKSHOP PROFILE

Expected Candidates

1. Managers in any Function/Domain

2. Executives in the Process Improvement Space

3. Executives in Quality Control/Assurance/Auditing

4. ISO 9001 Enthusiasts

5. Knowledge Aficionados

Schedule and Capacity

Date: Sunday, 16th July 2017

Time: 2.30pm to 6.30pm

Venue: PMtutor Office, 125A Apapa Road, behind Skye Bank, Costain Roundabout,

Capacity: Maximum of 4 Candidates

N/B: Though workshop is FREE, interested candidates must pay a registration fee of N10, 000 to GT Bank 0006403240 Oladipupo Akin-Tepede to book a seat. This fee covers all miscellaneous expenses associated with the workshop.

Course Content

1. Introduction and Types of DOE

2. Full Factorial Design

3. Blocking and Center point

4. Fractional Factorial Design

5. Response Optimization

Learning Objectives

1. Create and analyze factorial designs to find the optimal settings of multiple factors in a process.

2. Use blocking to account for unwanted variation in an experiment.

3. Use center points to detect curvature in the design space and estimate error without replicating corner points.

4. Create and analyze fractional factorial designs to find the optimal settings of multiple factors in a process without running a full design.

5. Using a Response Optimizer to find optimum factor settings.